Reduce post-launch defects and costly rework

Accelerate certifications and time-to-market

Improve product reliability across the full lifecycle

Minimize recall and compliance risks

Product failures are rarely caused by flawed ideas; they are more often the result of untested assumptions. As products become more complex and compliance-driven, even minor design gaps can escalate into large-scale operational and financial risks.

Studies show that companies embedding rigorous validation see 20–30% fewer defects and up to 20% reduced production costs, with 85% of manufacturing defects being preventable through proper quality control measures.

Early and structured validation not only reduces failure costs but also accelerates market entry. Organizations implementing effective testing and validation report up to 80% fewer post-release defects and faster time-to-market.

Furthermore, product recalls remain a material risk. Average recall costs range from $10 million to $100 million, with thousands of recall events recorded in 2024 alone. For industries that are highly regulated, the cost of non-compliance extends beyond dollars—it can block shipments, delay certifications, and erode customer trust.

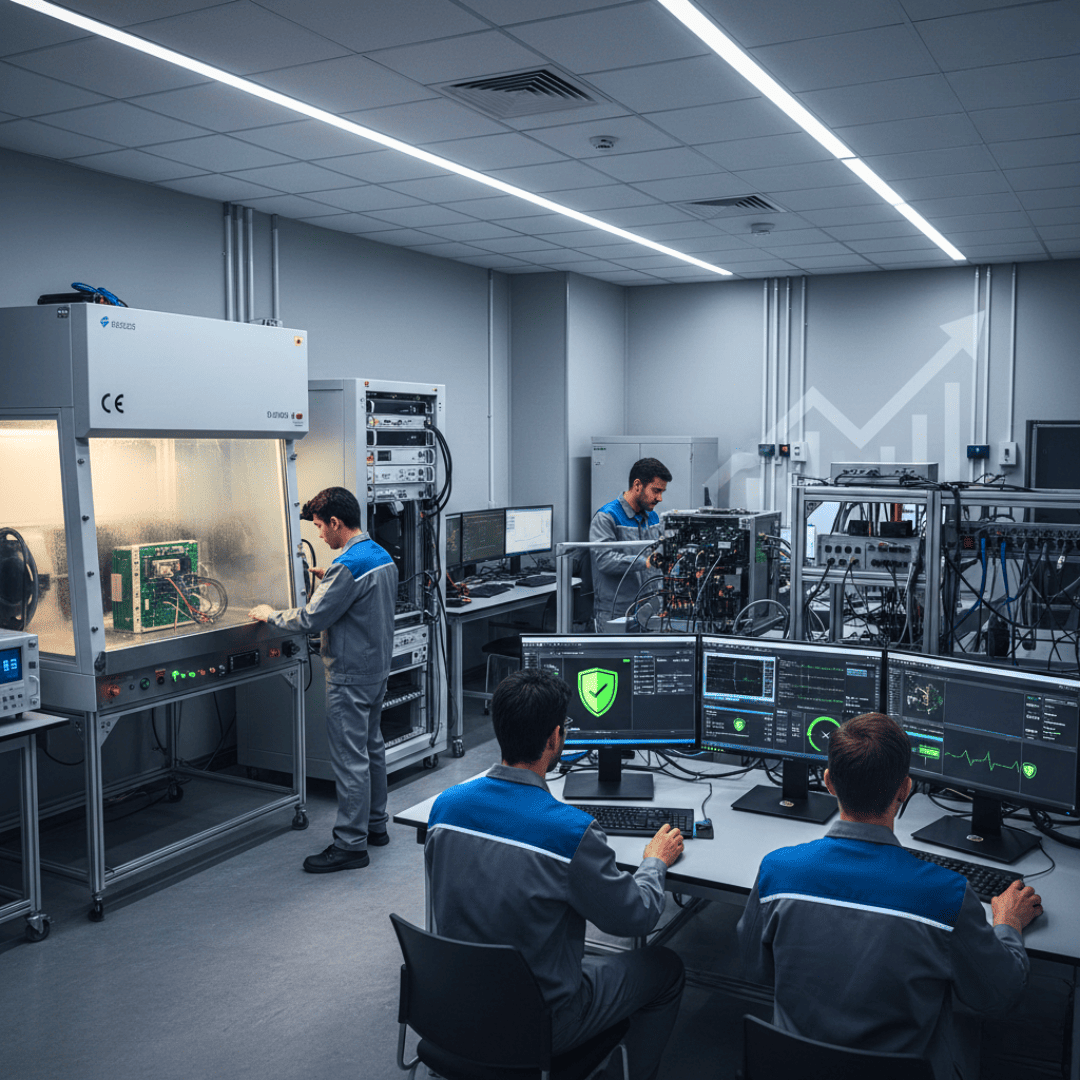

Effective product validation requires coordination across disciplines, tools, and testing environments. At Alpha ICT, validation is approached as a system-level exercise, spanning hardware, firmware, and software from early development through field deployment.

Our approach:

With experience across industrial controllers, HVAC systems, lab instruments, energy meters, digital access products, and asset tracking solutions, Alpha ICT applies domain knowledge to anticipate real-world performance considerations early in the validation process.

This structured approach supports 90% product reliability with 90% confidence, aligns with global compliance requirements, and effectively bridges the gap between controlled lab validation and real-world operating conditions.

Product validation has evolved into a strategic, lifecycle-driven practice that strengthens product readiness and long-term value. By embedding validation early, organizations streamline certifications, optimize development efforts, and build lasting customer confidence.

Whether launching a new product, expanding across markets, or enhancing existing designs, structured validation helps ensure products are scalable, compliant, and dependable in real-world operating conditions.

Connect with Alpha ICT to enable confident product launches and deliver solutions that perform—consistently, globally, and over time.